In the binding and finishing process, print coating is an activity in which a printed substrate (surface) is covered with a clear film, such as a lacquer, primer, or varnish. When merely a portion of a printed object is covered, this is known as spot coating. Coatings can either be water-based (aqueous) or ultraviolet/electron-beam. The former types of coats dry through evaporation, while the latter coatings dry via polymerization. When the coating process is done in the service of a business, it is called commercial print coating.

In the binding and finishing process, print coating is an activity in which a printed substrate (surface) is covered with a clear film, such as a lacquer, primer, or varnish. When merely a portion of a printed object is covered, this is known as spot coating. Coatings can either be water-based (aqueous) or ultraviolet/electron-beam. The former types of coats dry through evaporation, while the latter coatings dry via polymerization. When the coating process is done in the service of a business, it is called commercial print coating.

How Does Print Coating Work?

Coatings are normally composed of pigments and adhesives (or binders). The pigments may be made from either titanium dioxide (which improves opacity and brightness), refined clay (which creates more gloss), or calcium carbonate, which also improves brightness and absorbs the ink better. Binders are often made of natural materials such as starch or synthetic sources such as vinyl acrylic latices. Synthetic adhesives are more water-resistant (and resistant to cracking when the paper is folded) than their natural counterparts.

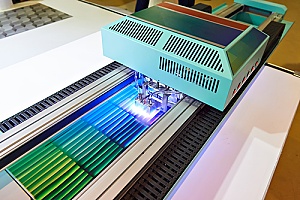

Several methods can be utilized to apply coatings, including papermaking machines, cast coaters, blade coaters, and air knife coaters. The amount of coating that is added to a substrate depends on the paper’s final basis weight, among other factors. When print coating, a paper’s runnability is also often considered. This term refers to the interactions of a paper’s properties and the ways they affect how this paper performs on press. Considerations such as a surface’s cleanliness and how well particles of coatings remain attached to the paper are taken into account when assessing runnability.

Benefits Of Commercial Print Coating

Print coating allows you to protect your graphics from becoming exposed to moisture or extreme temperatures. It also gives your designs a clean, professional look, which is always important to have for your business, regardless of whether it is newly minted or has been operating for years. Additionally, each type of coating has its own advantages. For example, aqueous coatings dry faster, won’t turn yellow over time, and are more eco-friendly. Ultraviolet coatings, meanwhile, yield the highest gloss and excellent clarity. The pigments contained in UV coatings are also typically chemical-resistant. Film laminates also do not yellow with age and are scratch-resistant. The type of coating you choose largely depends on your business’s unique needs and goals. A company that specializes in commercial printing services can help you match these needs.

Print coating allows you to protect your graphics from becoming exposed to moisture or extreme temperatures. It also gives your designs a clean, professional look, which is always important to have for your business, regardless of whether it is newly minted or has been operating for years. Additionally, each type of coating has its own advantages. For example, aqueous coatings dry faster, won’t turn yellow over time, and are more eco-friendly. Ultraviolet coatings, meanwhile, yield the highest gloss and excellent clarity. The pigments contained in UV coatings are also typically chemical-resistant. Film laminates also do not yellow with age and are scratch-resistant. The type of coating you choose largely depends on your business’s unique needs and goals. A company that specializes in commercial printing services can help you match these needs.

Get High-Quality Commercial Print Coating With PGI

Reach out to the specialists at Professional Graphics, Inc. to learn more about the print coating process and its benefits. Since 1979, we have been dedicated to providing high-quality commercial printing services at competitive rates. We use modern technology and always deliver our services on deadline and according to our clients’ budgets. Call PGI today at (203) 347-0215 or request a quote online for more information about our work.